Product

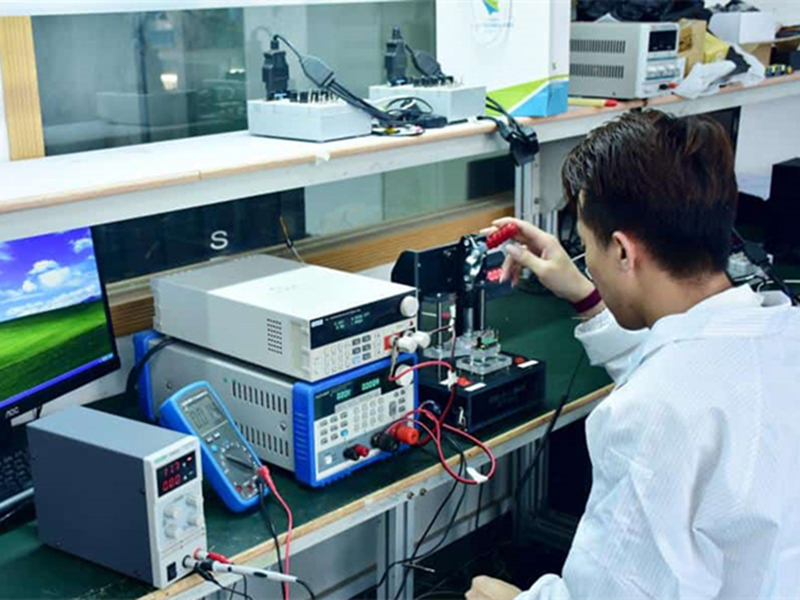

COMPREHENSIVE TESTING PLAN

Testing is a crucial part of the PCB Design & Assembly Process.

We work closely with our clients to identify the optimum testing requirements for each unique project. Our cutting-edge in-house testing capabilities enable us to carry out the most comprehensive and highly efficient test procedures across the entire production process and through to final inspection. Our customers can be confident that every PCB meets the same high-quality standards from start to finish.

We offer extensive PCBA process control, starting from the initial assembly stages to functional testing of different products. We carry out quality control for all products and processes and maintain high-performance analysis and debugging of electronic failures. We perform functional/Pre-functional dedicated ATP, burning, automatic Bl room, and analytical and diagnostic troubleshooting.

QUALITY CONTROL

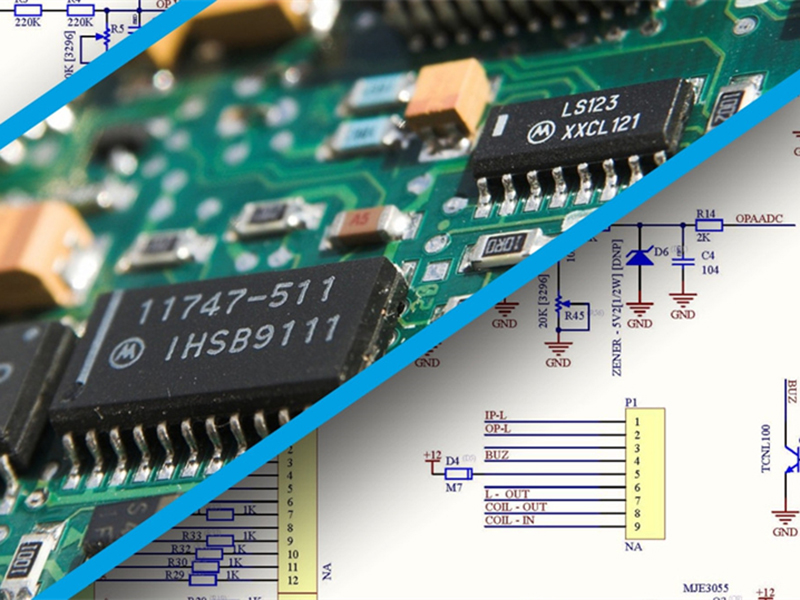

one -Stop Electronic manufacturing Services

COMPONET: professional purchasing team;the ability of purchasing hard-to-get materials;Original factory formal agent channel

MAN: strict employment rules; trainings for new employees; work license

Milieu (meaning environment)strict control of the production environment on dust, temperature and humidity;dust-free room,

Method: lPC- ll (if required, we can also do IPC-lll); operation instruments; production records.

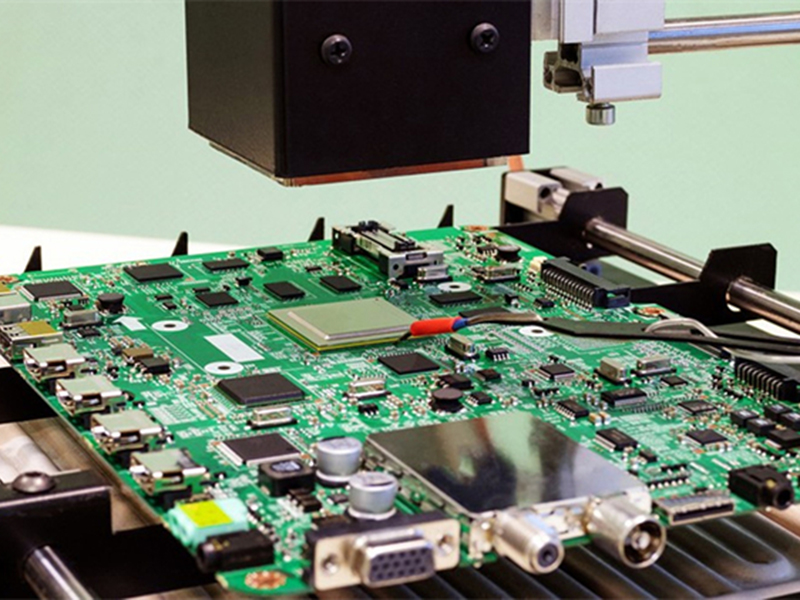

Machines: 2D/3D test instrument, AOI scanning equipment, AOl analysis equipment, E-test line; automatic immersion copper line, automatic plating line and so on,

QUALITY POLICY

Execute a system that assures Total Customer Satisfaction

QUALITY OBJECTIVE

Product pass rate:>99%

Timely delivery rate:>98%

Customer complaint rate:<1%

Customer satisfaction rate:>98%

CERTIFICATION

ISO9001:2015 | ISO14001:2015 | UL | CE | ROSH | CQE | IATF 16949:2016 | ISO 13485:2016

Categories

Latest News

Contact Us

Shenzhen Yuyuancheng Technology Co., Ltd.Web:www.yoyopcba.com

E-Mail:sales@yoyopcba.com

Tel: 86-0755-23226869

Fax:86-755-234959992

Add: Building No.201, Ma'anshan Garden, Shajing Street, Bao'an District, Shenzhen, Guangdong, 518104, China.